Keeping Roofs Safe Throughout the Year

Business and homeowners can never be too careful when it comes to maintaining their roofs. After all, this is where most weather related issues begin or end. So, it makes sense to inspect the roof at least twice a year and check for potential problems. Broken shingles or damaged flashing roof can result in expensive water damage down the road, so it’s vital to catch these problems before any damage can be done. For this reason, the National Roofing Contractors Association (NRCA) recommends that homeowners inspect their roof every spring and fall. Also check the roof after any major hail or wind storm. Regardless of a roof’s age, severe hail storms can cause serious damage.

When it comes to roof care, here are some important factors to keep in mind:

- Multiple-layer roofs (shingles laid over shingles) will have a shorter lifespan.

- An unventilated or poorly ventilated attic reduces roof lifespan.

- Tree branches rubbing on a roof or the accumulation of leaf debris on a roof can shorten the life of roof shingles.

- Severe weather such as hot summers and harsh winters can affect your roof. Weather fronts that introduce dramatic temperature swings within a 24-hour period can also shorten lifespan because of the rapid expansion and contraction of the roof materials.

What’s the Best Way to Heat a Roof?

ProLine Radiant offers several options when it comes to heating your roof. Each system can be easily customized to meet the specific snow removal demands and budget needs.

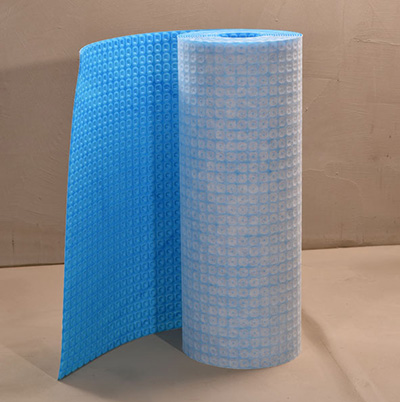

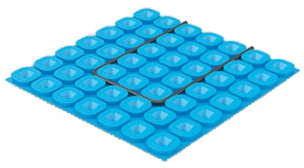

One of the most popular systems for heating roof edges is the RoofHeat low-voltage system. This system features thin, low-voltage heating element that is installed directly under the roof shingle. (The system is also safe to install under metal roofs.)

The semi-conductive polyethylene heating element comes in 12-inch wide rolls and can even be nailed or stapled through and cut on site. Other widths are available for heating gutters and downspouts. The heating element is polypropylene fused during fabrication to achieve water proofing and protection from alkaline or salt damage.

Heating Gutters and Downspouts

Self-regulating heat trace cable is the ideal solution for heating gutters and downspouts. The heat cable can be effectively used to heat roof edges and provide a channel for runoff, as well as routed through gutters and downspouts to help prevent costly ice and water damage, frost erosion and dangerous falling ice.

The self-regulating roof and gutter heat trace cable is effective and energy efficient. The durable UL listed cable meets the requirements of the NEC (National Electric Code) Section 426. Self-regulating cable features an irradiated conductive core that increases the heat output as the outside temperature falls and decreases the heat output as the temperature rises. This proven construction makes it tough, safe, and very energy efficient.

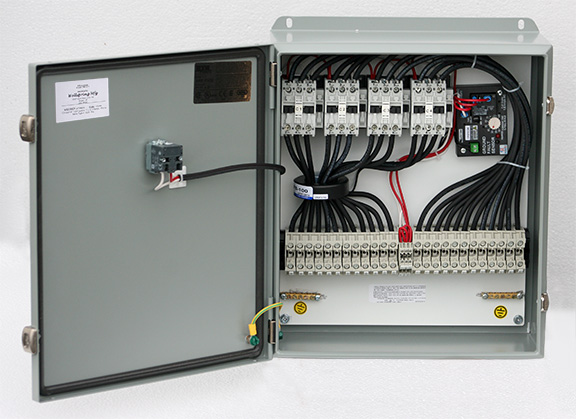

Most residential automated self-regulating heat trace systems consist of the heating element and a thermostat or snow sensor (activation device). Larger systems may require another contactor, depending upon the power requirements. Heat trace systems rely on the thermostat to signal the controller and activate the system to keep the gutters and downspouts clear of ice.

ProLine roof deicing systems are fully automated and maintenance free. Our roof heating systems have been installed throughout most cold regions around the country and are still the most effective and discreet for roof deicing and gutter trace applications.

Roof heating systems are easily customized to accommodate just about any roof type and configuration. ProLine self-regulating roof and gutter heat trace cable may also be combined with other recommended roof heating systems, such as the RoofHeat low-voltage deicing system to create an optimal solution for you. We’ll work with you to create a customized system to best accommodate your specific snow melting needs as well as your budget. For more information, call 866.676.9276 today.